Naval architects typically encounter the following problems when using traditional propeller designs on planing hulls:

On the one hand, there is the idea of using the largest possible propeller size to achieve maximum efficiency. However, this is generally not possible because the propeller shaft cannot be overly inclined and must comply with the clearance between the propeller and the hull to avoid hull vibration. On the other hand, the propeller must be submerged deep enough in the water to avoid cavitation. This dilemma leads designers to compromise one advantage for another.

The surface drive system solves these problems in design. It places the propeller in a recess above the hull, which is designed to reduce the contact between water and the hull, thus reducing resistance. Compared with traditional propeller designs, the propeller size of the surface drive system can be larger because its axis can be steeper, and the clearance between the propeller blades is no longer a limiting factor.

In addition, the surface drive system also uses an adjustable lifting system, which can adjust the height of the propeller according to the speed and water surface conditions of the vessel. This allows the vessel to maintain more stable speed and stability in different water surface conditions, and even in rough sea conditions, the vessel can be operated more easily.

Therefore, the design philosophy of the surface drive system aims to reduce resistance, improve efficiency, and provide sufficient power and maneuverability to enable the vessel to travel at high speed. It is an efficient, stable, and easy-to-operate propulsion system.

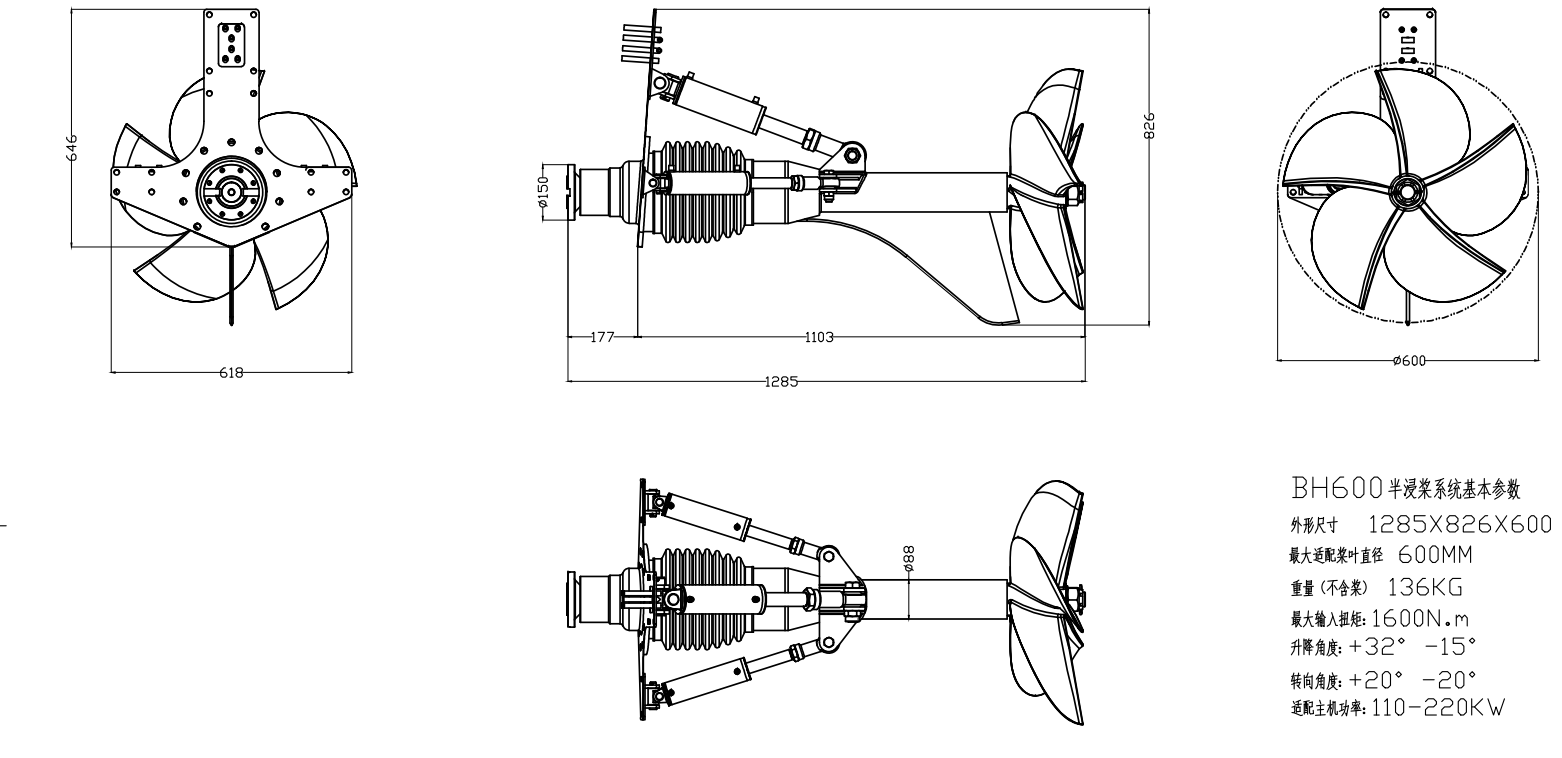

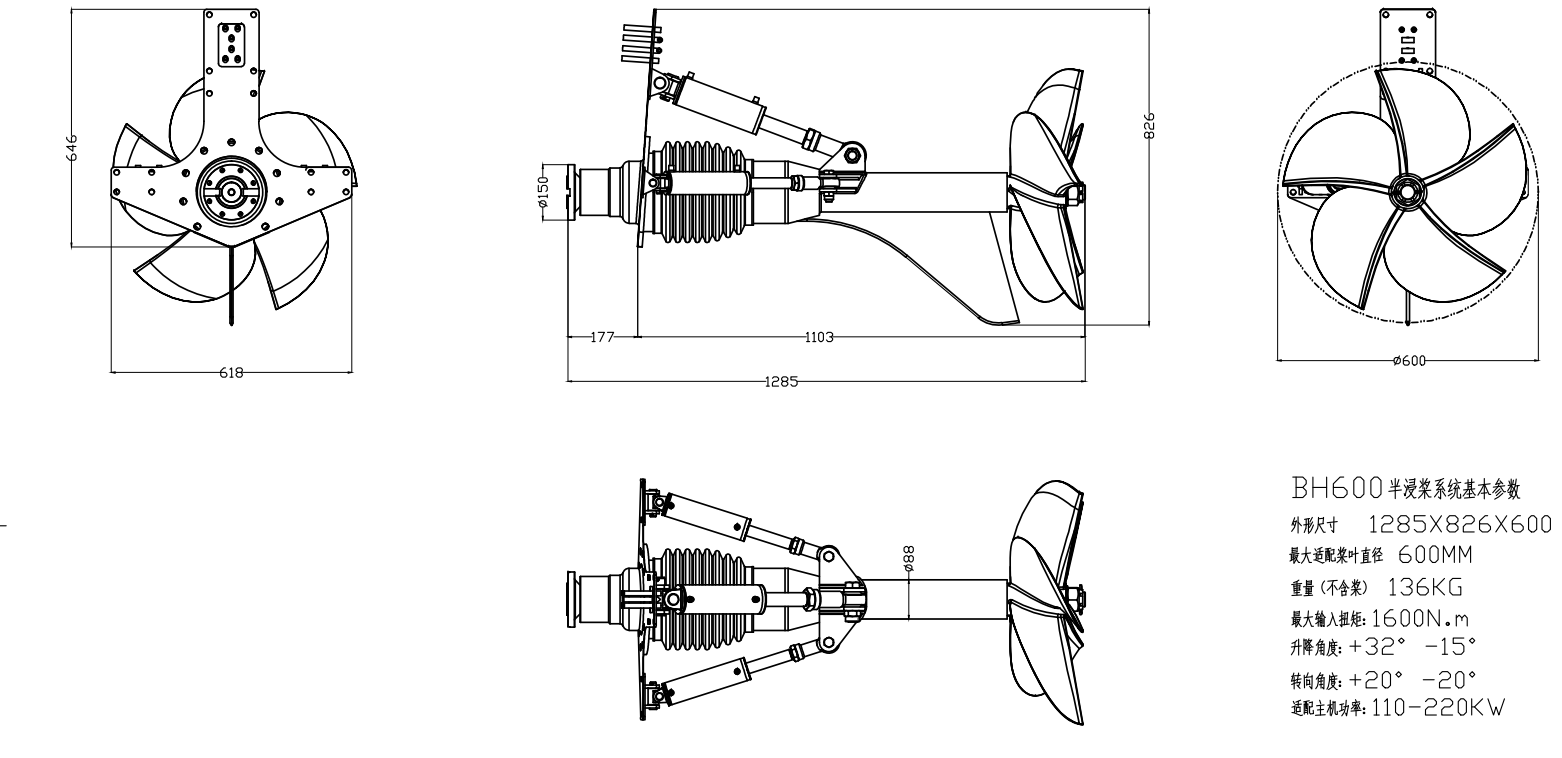

| BH600 |

| Adaptable blade diamete | 600 |

| Number of adaptable blade | 5 |

| Adapted power | 180-300ps |

| Maximum input torque N. | 1600 N.m |

| Weight | 136KG |

| Adapted ship weight | Single machine5T Dual machine11T |

| Standard accessories | Cardan shaft, hydraulic lifting station, lift table |

The correct position for installing a surface drive system:

The nut on the propeller blade should be positioned 10mm below the boat's transom extension line. However, for some light-loaded high-speed boats, the position may vary slightly, such as being 20mm below the transom extension line.

The main engine and the transmission shaft should form a straight line, not a large angle. If the engine is revved up and the prop system remains unchanged, the universal joint cage of the coupling will have an angle instead of a straight line, which can cause damage to the coupling cage over time.

While tilting the engine, the half-immersed propeller and the shaft should also be tilted at the same angle to form a straight line.