Key Features

- Advanced Hydraulic System | Smooth & Reliable Shifting

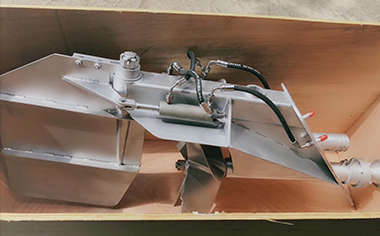

Equipped with a multi-plate hydraulic clutch and electronic shift control, ensuring seamless and precise gear transitions.

- Real-Time Monitoring & Smart Control | Optimized System Performance

Displays rudder angle, trim position, oil temperature, and oil pressure in real time, keeping the system in peak operating condition.

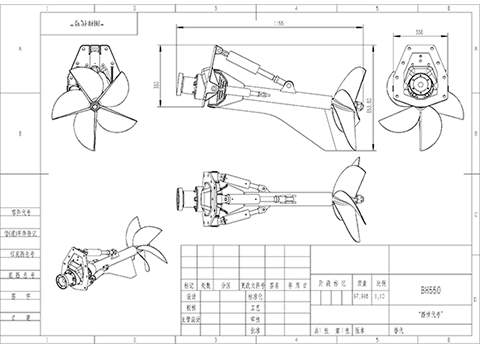

- Effortless Steering & Trim Adjustments | Precision Maneuverability

Features electro-hydraulic trim control and hydraulic steering, offering smooth, responsive handling and significantly enhancing the navigation experience.

- Robust & Efficient Power Transmission | Superior Durability

Utilizes large spiral bevel gears, twice the size of conventional sterndrive gears, ensuring greater reliability and longevity under high-performance conditions.

- Corrosion-Resistant Stainless Steel Construction | Built for Harsh Marine Environments

The housing is made of high-strength stainless steel, providing exceptional resistance to seawater corrosion and ensuring durability in demanding marine conditions.

- Enhanced Performance & Reduced Drag | High-Speed Efficiency

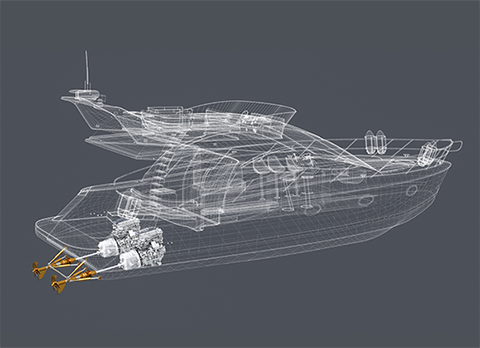

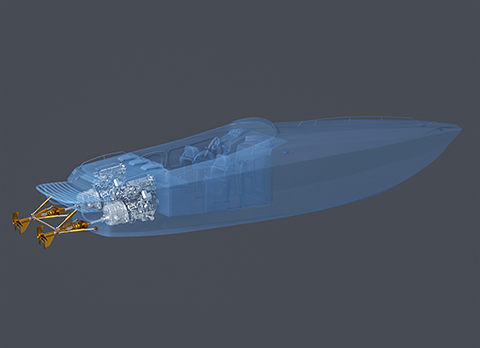

Designed for minimal hydrodynamic resistance and maximum propulsion efficiency, while also optimizing engine room space utilization for improved overall performance.

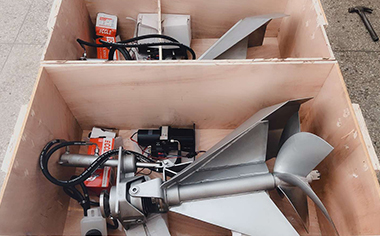

- Easy Installation & Maintenance | Cost-Effective Operation

With a streamlined design for quick installation, easy operation, and simplified maintenance, reducing long-term operating costs.

With cutting-edge technology, precision engineering, and exceptional handling performance, the TSD Integrated Semi-Submerged Propulsion System delivers powerful, efficient, and reliable propulsion for high-speed boats and yachts. It sets a new industry standard, offering an innovative solution for modern marine propulsion.