-

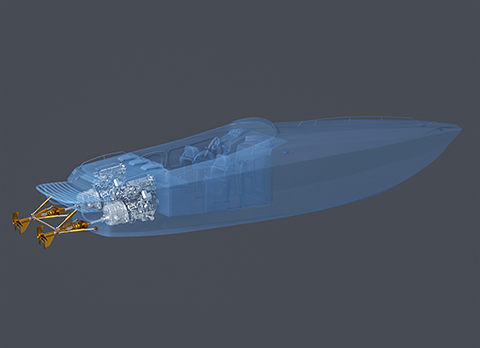

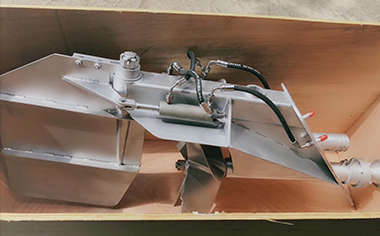

Q The correct position for installing a surface drive system

A The correct position for installing a surface drive system:

The nut on the propeller blade should be positioned 10mm below the boat's transom extension line. However, for some light-loaded high-speed boats, the position may vary slightly, such as being 20mm below the transom extension line.

The main engine and the transmission shaft should form a straight line, not a large angle. If the engine is revved up and the prop system remains unchanged, the universal joint cage of the coupling will have an angle instead of a straight line, which can cause damage to the coupling cage over time.

While tilting the engine, the half-immersed propeller and the shaft should also be tilted at the same angle to form a straight line.

-

Q How long is the warranty period for surface drive systems?

A The warranty period for surface drive systems is typically 18 months, which means that within this period, if there is any malfunction or damage to the parts, the customer can return the damaged parts to the manufacturer for repair or replacement. During the warranty period, the manufacturer will provide free parts and technical support. If the equipment fails or is damaged outside the warranty period, the customer needs to purchase the corresponding parts from the manufacturer and the manufacturer will provide technical support. During the warranty period, only damaged parts are covered by the warranty, and not the damage caused by normal use, which the user will have to bear. The responsibility for shipping costs will also differ depending on whether it is within or outside the warranty period, and specific details need to be checked in the manufacturer's warranty terms and conditions.

-

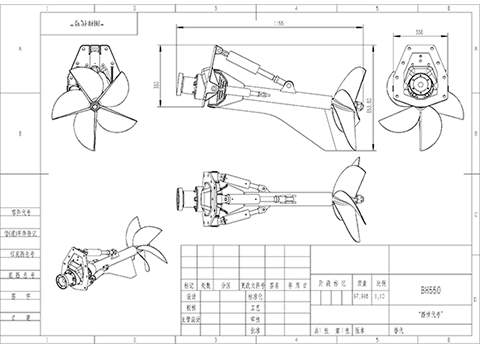

Q Installation angles for BG and BH surface drive systems

A Surface drive systems typically come in two installation types: BG and BH. These installation types have different installation angles.

The installation angle for a BG surface drive system is 45 degrees.

The installation angle for a BH surface drive system is 10-13 degrees.

If the installation angle is outside of these ranges, a stainless steel box is needed to connect the surface drive system.

-

Q How long is the service life of the surface drive system?

A The lifespan of a surface drive system depends on various factors, such as the usage environment, frequency of use, maintenance, and so on. In a good environment, the lifespan of a surface drive system can usually be over 10 years. However, in extreme environments, such as waters with high humidity up to 95%, water temperature up to 38℃, and high salt content, the lifespan of surface drives may be shortened to around 5-6 years. Regular maintenance is necessary to ensure the normal operation and extend the lifespan of the surface drive system.

-

Q How to Maintain Surface Drive Systems and Prevent Corrosion?

A Cleaning: Regularly clean the surface drive system with soap and water to prevent the formation of marine organisms and scale. Lubrication: Replace the oil seal and lubricating oil every 1000 hours. This will help prevent excessive wear on the surface drive system.

Replace the corrosion-resistant zinc block: The surface drive system is usually equipped with a corrosion-resistant zinc block to prevent seawater corrosion and weaken the corrosion of the drive system by seawater. If the zinc block is severely corroded, it needs to be replaced with a new one.

Regular Inspection: The surface drive system should be regularly inspected to ensure that all parts of the drive system are in normal working condition. The inspection should include wires, cables, and all connection components.

-

Q Difference Between Surface Drive Systems with different Numbers of Blades

A The main difference between surface drive systems with different numbers of blades is their performance range and adaptability to different load conditions.

Regarding the specific blade number selection, a 4-blade system generates less propulsion force and is suitable for low-speed and light-load situations. A 6-blade system provides more propulsion force and is suitable for full-load conditions. A 5- The blade system can balance and consider both light and full-load situations, providing moderate propulsion force and higher speed, thus being widely used in different types of vessels.

-

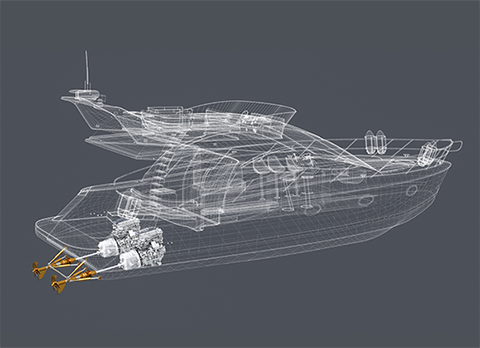

Q The Difference Between BH and BG Surface Drive Systems

A BH and BG surface drive systems differ mainly in their mobility. BH surface drive is mobile, allowing it to turn left and right and move up and down to avoid damage from underwater obstacles, thus increasing the lifespan of the propeller. On the other hand, BG surface drive is fixed and lacks the up-and-down movement function, but it shares the same functions as BH surface drive. The advantage of BG surface drive is its relatively lower cost-effectiveness, as it does not require moving parts, resulting in lower manufacturing costs.

In terms of installation, BG surface drive requires an angle of approximately 45 degrees at the stern of the boat for installation. If the angle difference is too great, an additional box must be purchased to adjust the installation angle. BH surface drive, on the other hand, has no special installation requirements.

-

Q How to choose the gear ratio for a gearbox?

A The gear ratio of the gearbox is usually adjusted based on the torque of the surface drive. The reduction ratio = propeller torque: engine torque; for example, if the propeller torque is 600 and the engine torque is 400, then the reduction ratio of the gearbox is 600:400=1.5:1.

When matching a gearbox for customers who already have an engine, it is necessary to have a detailed understanding of the engine's rated power, torque curve, maximum torque, and other data. These data will help determine the accurate reduction ratio of the gearbox.

It should be noted that the reduction ratio of the gearbox is generally determined before leaving the factory and cannot be adjusted arbitrarily during use.

-

Q How to choose an engine to use with a surface drive system?

A The following factors need to be considered: Power output: A surface drive system requires a high-speed and efficient propeller, so an engine with a high speed of 2000 RPM or more should be selected.

Inboard use: A surface drive system needs to be connected to the engine and gearbox for inboard use, so an engine suitable for inboard use should be chosen.

Reliability and maintainability: A reliable and easy-to-maintain engine should be chosen to ensure stability and reliability in long-term use.

Environmental friendliness and fuel efficiency: An engine that meets environmental standards should be selected, and one with high fuel efficiency can reduce fuel consumption and environmental impact.

-

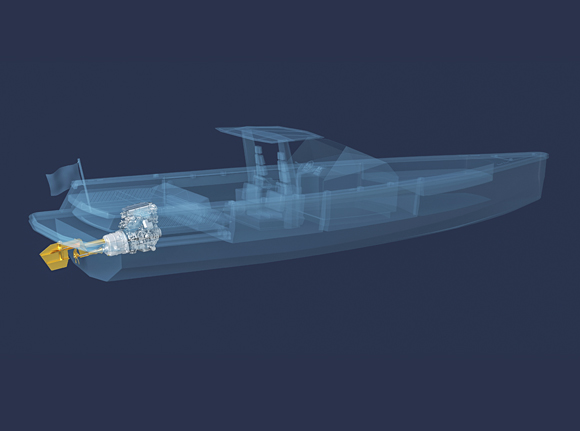

Q The Operating Principle of Surface Drive Systems

A Surface drive systems are a type of marine propulsion system that utilizes the pressure difference between the hull and the water surface to generate propulsion. During low-speed operation, the propeller blades are fully submerged and push the vessel in a conventional manner. However, during High-speed operation, the hull automatically lifts, exposing half of the propeller blades to reduce water resistance and increase propulsion force.

When the propeller blade height needs to be adjusted, the crew can use lift buttons to control the blade position to adapt to different navigation conditions. Surface drive systems are widely used in high-speed yachts, military ships, commercial vessels, and other fields to increase ship speed and reduce fuel consumption.